Image Scanning Troubleshooting

This article will review the most common image scanning problems and how to solve them

Typical Problems Include

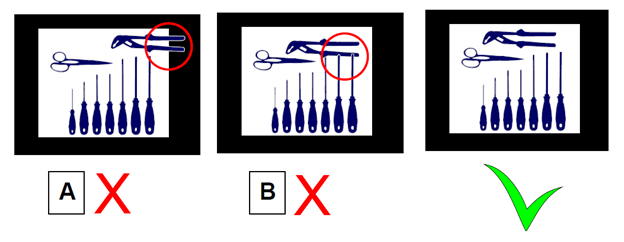

- Operator zoomed in too much and did not include the frame of the Light Box in the picture.

- Operator allowed something unintended to cover the frame of the Light Panel

- Part is too large for the Light Box and overhangs the frame on the Light Panel

- Clear plastic part on the Light Box did not scan correctly.

- A good example of this is a clear plastic handle of a screwdriver

- Operator did not turn the Light Box on

- Tall parts require the camera to be very straight

To test that your Light Panel is providing images that scan into the correct size we recommend using a test object. For example snapping an image of a ruler and using it to reference that the image scan is measuring correctly.

Taking a Photo Correctly

- Be sure the camera is flat - or - 90 degrees from the light panel surface

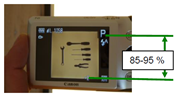

- Zoom in on the light panel and fill 85% to 90% of the camera window with the light panel. Ensure that the frame of the light panel is visible in the picture

- Make sure all tools are sitting on the light panel's lit surface and not overlapping.

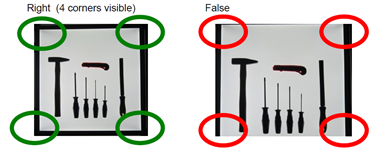

- All 4 corners should be visible in the photo

Light panel photos should have a minimum distance of 1.5 M (4.9 feet). However it is important to consider that the OSAAP scanning process is most commonly used with tools that are less than 1 1/2" thick (1.5" is 2.5% of 4.9') which will result in very little shadowing. As your parts get thicker than 1 1/2" we recommend applying a 2X general-rule: increase the distance between the camera and the light panel by 2X the part thickness for parts thicker than 1 1/2".

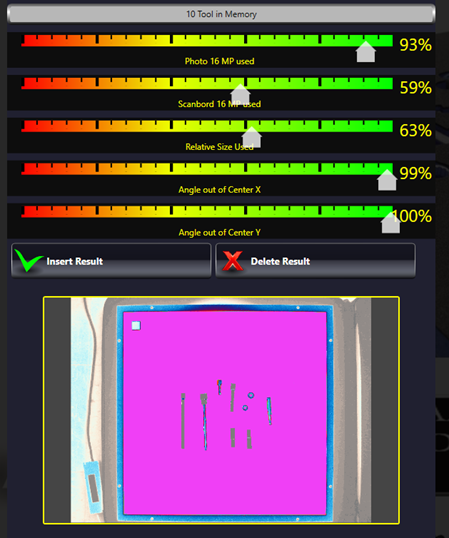

What does a good image scan look like?

- Photo 16 MP used should be <90%

- Scanbord 16 MP used should be <50%

- Relative Size used should be <50%

- Relative Size used should be <97%

- Angle out of Center Y should be >97%, <102%